At ECHOIC, we operate a full prototyping facility for long-term research and development.

PCB assembly and prototyping

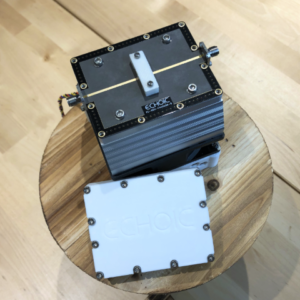

We operate a LPKF Protomat S62 60,000 RPM PCB mill for prototyping high performance microwave circuits for industrial applications. In-house PCB prototyping is advantageous for non-standard materials such as Rogers and Taconic as well as for confidential development. We also use the mill for transistor test fixture fabrication and antenna prototyping.

Echoic Engineering is also an expert in RF PCB tuning and can only be learned through years of experience. During the product development cycle, it is critical to maintain a tightly integrated design, test, measure and tuning flow. The shorter this iterative loop is, the faster the design specifications will be met. Fortunately, Echoic Engineering has the capability to perform all SMD assembly and PCB modification in-house and can deliver a spec-compliant part faster than others.

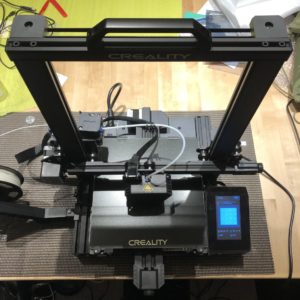

Mechanical

For mechanical design, Echoic Engineering employs a CNC mill and 3D printer for producing prototype housings and small parts. Our CNC mill is capable of milling 6061 aluminum, wood and plastics. Our 3D printer prints on PLA plastic and can produce prototypes prior to sending out to a professional-grade printer.

Precision crafted test fixtures enable the accurate measurement of GaN RF transistors and power amplifiers. Our custom development kits provide a low loss interface and effective thermal solution for your transistor characterization and modeling needs.

Microcontroller Coding

For advanced product development requiring user-interfacing, digital signal processing (DSP) and systems control, Echoic Engineering employs a range of Arduino-compatible MCUs. In addition, a variety of screens, sensors and controllers can be coupled together to suit any application.

Please contact us with your needs.